Maszyny i farby drukarskie - Tampo Granit z Warszawy

Specjalizujemy się w technice tampodruku i sitodruku. Oferujemy maszyny do tampodruku, standardowe i specjalizowane, które zaspokoją potrzeby większości ich użytkowników.

Ponadto, jako przedstawiciel niemieckiej firmy Coates Screen Inks GmbH, zaopatrujemy klientów w farby do tampodruku i farby do sitodruku.

Ofertę naszą uzupełniają tampony niemieckiej firmy Morlock.

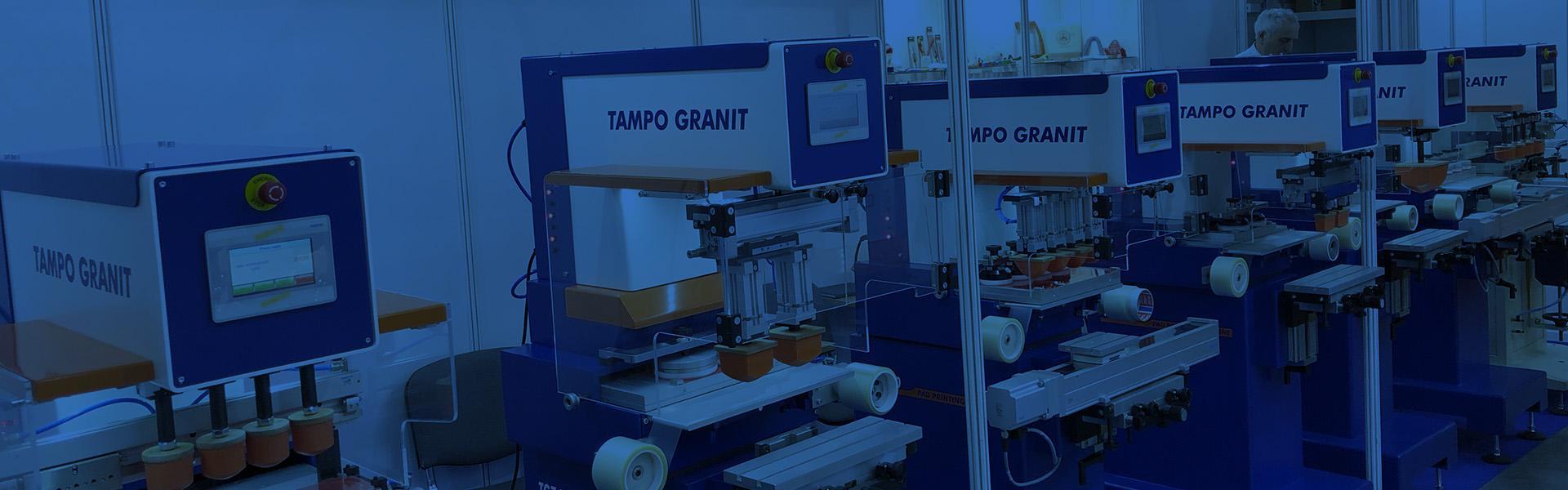

Producent tampodrukarek

Jesteśmy producentem maszyn do tampodruku znanych pod popularnymi nazwami tamponiarki lub tampodrukarki.

Tamponiarka to urządzenie dzięki któremu możliwe jest nanoszenie nadruków na powierzchniach o dowolnym kształcie, wykonanych z różnego rodzaju materiałów.

Zastosowanie tych maszyn jest wszechstronne i pozwala na precyzyjne nadrukowanie np. logotypu na gadżetach reklamowych (długopisy, kubki, etc.) czy też opisów i zdobień na wyrobach produkcyjnych (np. kondensatory, czajniki i wiele innych).

Maszyny produkowane są w oparciu o najnowsze technologie i wyposażone w podzespoły renomowanych firm, co gwarantuje ich wysoką precyzję, funkcjonalność i niezawodność.